Application Briefs

-

MULTI-CONDUCTOR CABLE HIPOT AND CONTINUITY TEST SYSTEM

Emerging Technologies, LLC. was called upon to provide a replacement multi-conductor cable test system. An existing test system was in place and failing due to age.

Click the image for more info.

-

AUTOMATIC TRANSFER SWITCH TEST SYSTEM

-

SERVO BASED DUT ROTARY CYCLING SYSTEM

-

SWITCH FORCE SUB-ASSEMBLY TEST SYSTEMS

-

MICROCONTROLLER-BASED SUB-ASSEMBLY TEST SYSTEM

-

PRESSURE LEAK TEST SYSTEM

-

HIGH PRESSURE LEAK TESTER

-

ELECTRO-MECHANICAL SUB-ASSEMBLY TEST SYSTEM

-

AUTOMATED DEFLECTION DURABILITY TEST FIXTURE

-

DUPLICATE ASSEMBLY CARTS

-

AUTOMATED ASSEMBLY CART

-

OVERLOAD RELAY END OF LINE TEST SYSTEM

Emerging Technologies, LLC. was called upon to design and build an End Of Line test system with laser marking. The DUT was to be configured, tested, and marked.

Click the image for more info.

-

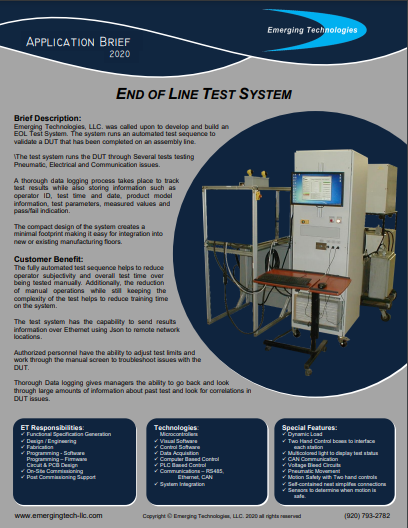

END OF LINE TEST SYSTEM

-

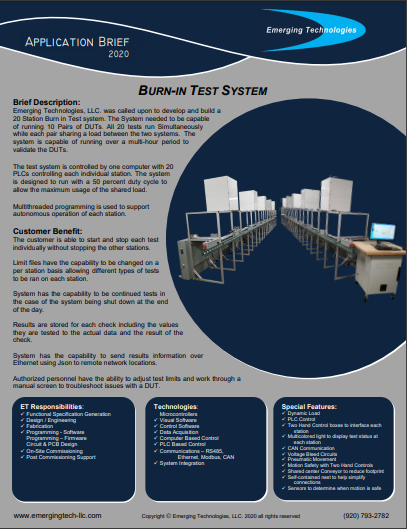

BURN-IN TEST SYSTEM

-

1,100 AMP VARIABLE MOBILE AC CURRENT SOURCE

-

HALL EFFECT SENSOR CALIBRATION SYSTEM

-

HIGH SPEED DAQ AND CONTROL SYSTEM

-

CUSTOM CONFIGURATION READER INTERFACE

-

TILTING FIXTURE FUNCTIONAL TEST SYSTEM

-

MANUAL TEST CONSOLE